Advanced Driver Assistance Systems (ADAS) rely on precise sensor data for safety features like adaptive cruise control and automatic emergency braking. After repairs or adjustments, specialized ADAS recalibration equipment is crucial to restore system accuracy and reliability. Skipping this step poses significant safety risks due to misaligned sensors, impacting critical ADAS functions. Regular maintenance, including proper recalibration, enhances driving safety, preserves vehicle value, and ensures optimal performance capabilities for modern vehicles' advanced safety systems.

In today’s automotive landscape, Advanced Driver Assistance Systems (ADAS) play a crucial role in enhancing safety. However, skipping essential maintenance like ADAS recalibration equipment after repairs can introduce significant risks. This article delves into the vital role of this equipment and its impact on system accuracy. We explore potential hazards, from compromised collision avoidance to misjudged lane keeping, underscoring why calibration is non-negotiable. Discover best practices to ensure optimal ADAS performance and continued passenger safety.

- Understanding ADAS Recalibration Equipment and Its Role in Safety

- Potential Hazards of Omitting Calibration After Repairs

- Best Practices for Maintaining Optimal ADAS Performance and Safety

Understanding ADAS Recalibration Equipment and Its Role in Safety

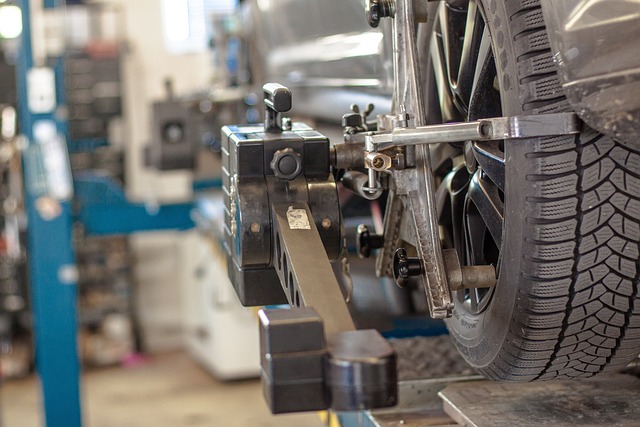

ADAS recalibration equipment plays a pivotal role in maintaining the safety and efficiency of modern vehicles equipped with Advanced Driver Assistance Systems (ADAS). These systems, including features like adaptive cruise control, lane-keeping assist, and automatic emergency braking, rely on precise sensor data to function optimally. After repairs or adjustments to these sensors or related components, ADAS recalibration equipment is essential to restore the system’s accuracy and reliability. Skipping this crucial step can lead to safety risks as misaligned or malfunctioning ADAS could result in accidents.

Proper ADAS recalibration involves specialized tools that resync the systems with the vehicle’s frame and ensure the data received by these sensors accurately reflects the real-world environment. This is particularly important after repairs, such as those involving a car dent repair or paintless dent repair, which may impact sensor positioning or sensitivity. Regular auto maintenance that includes ADAS recalibration not only enhances safety but also helps preserve the vehicle’s value and performance capabilities.

Potential Hazards of Omitting Calibration After Repairs

Skipping ADAS recalibration equipment after repairs can lead to significant safety hazards on the road. Advanced Driver-Assistance Systems (ADAS) rely on precise calibration to function optimally, ensuring features like adaptive cruise control, lane departure warning, and automatic emergency braking work correctly. Omission of this critical step post-repair may result in inaccurate sensor readings, causing these systems to malfunction.

In an auto collision repair or maintenance setting, it’s not uncommon for ADAS components to be affected. Even minor accidents can disrupt the delicate balance of these sensors, leading to potentially dangerous situations. Therefore, utilizing specialized ADAS recalibration equipment is essential to reset and calibrate these systems accurately. This process ensures that your vehicle behaves as intended, enhancing safety features rather than compromising them during daily driving.

Best Practices for Maintaining Optimal ADAS Performance and Safety

To maintain optimal Advanced Driver Assistance Systems (ADAS) performance and safety, best practices dictate a consistent use of dedicated ADAS recalibration equipment after any repairs involving auto bodywork or auto collision repair. Skipping this crucial step can lead to compromised sensor accuracy, which in turn can negatively impact the effectiveness of critical safety features like adaptive cruise control, lane departure warning, and automatic emergency braking. Regular calibration ensures these systems operate with precision, allowing drivers to confidently navigate even the most challenging road conditions.

Following industry standards and guidelines, including those recommended by vehicle manufacturers, is essential. This involves not only using high-quality ADAS recalibration equipment but also following proper procedures during the recalibration process. An automotive body shop that prioritizes these practices can significantly reduce potential safety risks and enhance customer satisfaction by delivering vehicles with reliable, safe, and fully functional ADAS systems.

Skipping ADAS recalibration equipment after vehicle repairs can lead to serious safety risks, compromising advanced driver-assistance systems’ (ADAS) effectiveness. As these systems rely on precise sensor calibration for optimal performance, omitting recalibration may result in inaccurate data, causing potential hazards on the road. To ensure maximum safety and reliability, adhering to recommended maintenance practices, including timely ADAS recalibration, is paramount.