Blind Spot Monitoring (BSM) relies on ADAS recalibration equipment for regular sensor calibration to maintain accuracy and reliability. Over time, sensors can drift, leading to false readings and reduced detection capabilities. Proper recalibration enhances safety by preventing accidents caused by unseen obstacles during lane changes or backing up, ensuring optimal sensor performance within their designated ranges.

Advanced Driver Assistance Systems (ADAS) have revolutionized safety on the roads, with Blind Spot Monitoring (BSM) as a key feature. This technology helps drivers detect vehicles in their blind spots, preventing potential collisions. However, maintaining optimal performance requires regular calibration, where ADAS recalibration equipment plays a pivotal role. By ensuring precise sensor alignment and data accuracy, this specialized gear enhances BSM effectiveness, ultimately fostering safer driving experiences.

- Understanding Blind Spot Monitoring in ADAS

- The Role of Recalibration Equipment

- Enhanced Safety Through Accurate Calibration

Understanding Blind Spot Monitoring in ADAS

Blind Spot Monitoring (BSM) is a crucial safety feature in Advanced Driver Assistance Systems (ADAS). It uses sensors and cameras to detect vehicles or objects in areas that the driver’s side mirrors cannot cover, known as blind spots. This technology alerts drivers of potential hazards when changing lanes or backing up, helping to prevent accidents caused by unseen obstacles. ADAS recalibration equipment plays a vital role in ensuring the accuracy and reliability of BSM, especially during vehicle maintenance or after certain repairs.

Regular calibration is essential for maintaining the performance of BSM sensors, which include radar, cameras, and ultrasonic sensors. Over time, these components can drift out of alignment, leading to false readings and reduced detection capabilities. ADAS recalibration equipment facilitates precise adjustments, ensuring that each sensor functions optimally within its designated range. This is particularly important in modern vehicles where complex ADAS systems are integrated into the vehicle’s electrical architecture, requiring specialized tools for accurate realignments. Whether it’s a routine service check or post-collision repair, using the right ADAS recalibration equipment helps keep blind spot monitoring at peak performance, enhancing overall safety on the road.

The Role of Recalibration Equipment

The role of ADAS recalibration equipment is pivotal in ensuring the accuracy and reliability of Advanced Driver Assistance Systems (ADAS) within a vehicle. As these systems, which include Blind Spot Monitoring (BSM), rely on precise sensor data, regular calibration is essential to maintain their effectiveness. Over time, sensors can drift or become misaligned, leading to potential safety risks. This is where specialized recalibration equipment comes into play, offering collision repair shops and auto body repair professionals a powerful tool to keep up with modern vehicle technology.

By using advanced tools designed for ADAS recalibration, technicians can accurately realign and calibrate sensors, ensuring they provide the correct data to the BSM and other ADAS features. This process is particularly crucial in today’s bustling automotive landscape where safety systems are intricately integrated into a vehicle’s overall design. Proper recalibration not only enhances collision repair outcomes but also contributes to the longevity of these sophisticated safety mechanisms, ultimately fostering a safer driving experience for everyone on the road.

Enhanced Safety Through Accurate Calibration

Accurate calibration is key to enhancing safety features like blind spot monitoring systems (BSM), where ADAS recalibration equipment plays a pivotal role. BSM relies on precise sensor positioning and data interpretation to detect vehicles in adjacent lanes, warning drivers of potential collisions. However, these sensors can drift over time due to various factors, affecting their accuracy. Here’s where specialized ADAS recalibration tools become indispensable.

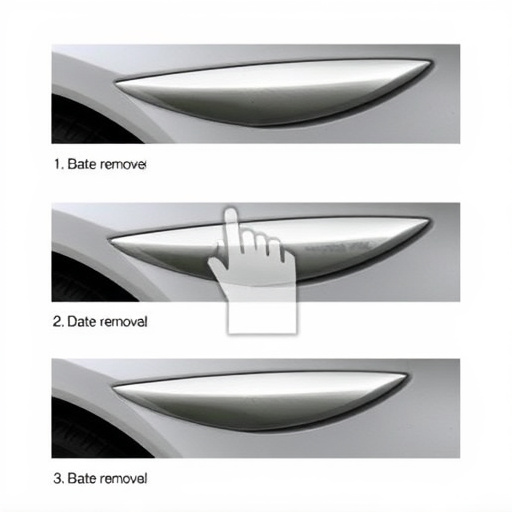

Regular calibration ensures that the blind spot monitoring system functions optimally, allowing for quick detection and response to nearby hazards. With advanced technologies like laser scanners and high-resolution cameras, this equipment facilitates precise adjustments, compensating for sensor shifts caused by fender repair, paintless dent repair, or other car body restoration processes. Thus, it’s not just about maintaining the integrity of these safety systems but also ensuring that vehicles on the road are equipped to react swiftly in potential dangerous situations.

ADAS recalibration equipment plays a pivotal role in enhancing blind spot monitoring, ensuring safer driving. By accurately calibrating sensors, this technology allows vehicles to detect and warn drivers about potential hazards in their blind spots, reducing the risk of accidents. As autonomous driving systems continue to evolve, regular calibration checks using specialized equipment become essential for maintaining optimal performance and maximizing passenger safety.