ADAS recalibration equipment is vital for modern automobiles, ensuring advanced safety features like adaptive cruise control and lane-keeping assist function accurately. Improper setup, even after minor body work, can lead to critical system errors. Car bodywork services should prioritize strict adherence to manufacturer guidelines during recalibration, controlling environmental factors to maintain accuracy. Meticulous best practices, including workspace preparation, handling delicate parts safely, and correct electrical connections, are essential for optimal ADAS performance and enhanced road safety.

In today’s automotive landscape, Advanced Driver Assistance Systems (ADAS) rely on precise calibration for optimal performance. However, improper setup of ADAS recalibration equipment can significantly impact results, leading to inaccurate sensor readings and compromised safety features. This article delves into the intricacies of ADAS recalibration equipment, exploring how setup errors affect accuracy and offering best practices to ensure optimal outcomes during recalibration, ultimately enhancing vehicle safety and functionality.

- Understanding ADAS Recalibration Equipment and its Functionality

- The Impact of Improper Setup on Recalibration Accuracy

- Best Practices for Setting Up ADAS Recalibration Equipment to Ensure Optimal Results

Understanding ADAS Recalibration Equipment and its Functionality

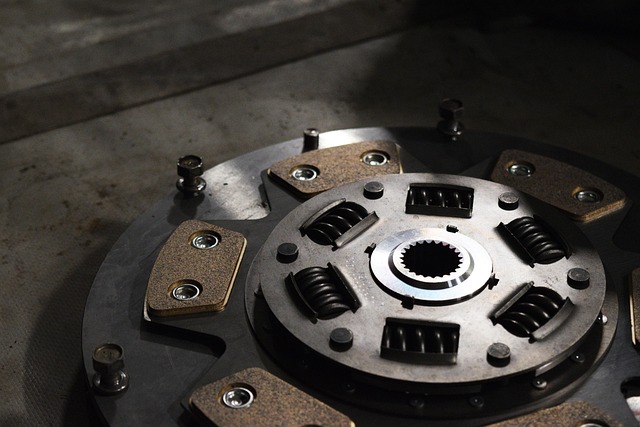

ADAS recalibration equipment is designed to fine-tune and adjust the performance of Advanced Driver Assistance Systems (ADAS) in vehicles, ensuring they operate at peak accuracy. This technology plays a crucial role in modern automobiles, offering features like adaptive cruise control, lane-keeping assist, and collision avoidance systems. The equipment typically includes sensors, cameras, and sophisticated software that work together to calibrate and recalibrate these systems as needed.

Proper setup is vital for ADAS recalibration equipment to function effectively. This involves precise placement of sensors and cameras, ensuring optimal visibility and data collection. An improperly set up system can lead to inaccurate readings and, consequently, subpar performance in ADAS functions. For instance, a fender repair or mercedes benz repair that alters the vehicle’s body structure might require recalibration to maintain the integrity of safety systems like lane departure warning. Car bodywork services should consider these calibrations to ensure customer safety and the optimal operation of their vehicles’ advanced driver assistance features.

The Impact of Improper Setup on Recalibration Accuracy

Improper setup during ADAS recalibration equipment use can significantly impact the accuracy and reliability of results. Each step in the process—from sensor positioning to environmental controls—must be meticulously executed according to manufacturer guidelines. Even minor deviations can introduce errors, leading to off-target adjustments in a vehicle’s advanced driver-assistance systems (ADAS). This is particularly critical for features like adaptive cruise control, lane departure warning, and automatic emergency braking, which rely on precise sensor calibration for optimal performance and safety.

Consider the example of car dent repair or car paint repair, where misaligned panels or faulty paints can skew pressure readings or light sensors, negatively affecting ADAS recalibration. Similarly, vehicle repair services that overlook proper environmental conditions, such as maintaining the correct temperature and humidity levels, risk compromising the integrity of recalibration results. Ensuring meticulous setup procedures is paramount to achieving accurate adjustments with ADAS recalibration equipment, ultimately enhancing road safety for all drivers.

Best Practices for Setting Up ADAS Recalibration Equipment to Ensure Optimal Results

When setting up ADAS recalibration equipment, adherence to best practices is paramount to ensure optimal results. The first step involves ensuring the workspace is clean, well-lit, and free from any debris or contaminants that could interfere with precise measurements. Proper environmental control, including temperature and humidity regulation, is crucial as these factors can significantly impact sensor accuracy.

Next, carefully inspect all components of the ADAS recalibration equipment to verify their integrity and functionality. Calibrated sensors, cameras, and radar modules are essential for accurate data capture. Prioritize safe handling during installation, especially when dealing with delicate parts like fenders (from auto collision repair) or paint jobs (car paint repair). Proper grounding and electrical connections are also vital to maintain stability and prevent interference from external sources, ensuring the entire process aligns seamlessly with the manufacturer’s guidelines for optimal performance.

In conclusion, proper setup of ADAS recalibration equipment is paramount to achieving accurate and reliable results. Understanding the device’s functionality and adhering to best practices can significantly impact the overall performance of Advanced Driver-Assistance Systems (ADAS). By ensuring meticulous calibration, we can optimize safety features, enhance vehicle dynamics, and ultimately contribute to a smoother and more secure driving experience.